PhD Opportunities

Discover more about our exciting training programme and how to apply for a PhD with us!

Find out moreAcademic Supervisors

Find out how academics at our partners can submit to the Materials 4.0 project calls!

Find out moreIndustry Collaborators

Learn about opportunities to fund studentships, collaborate with our academics, or support your staff in a “PhD at work”

Find out moreApply for a PhD

We have a range of projects that involve all aspects of Materials 4.0 and span across the Royce research areas. New PhD projects will be posted on this page each year in advance of each cohort. You can also sign up as an expression of interest here and we will let you know when new projects become available.

We encourage prospective PhD researchers to reach out to the relevant project supervisors with questions about their projects before you complete an application.

Why do a PhD with us?

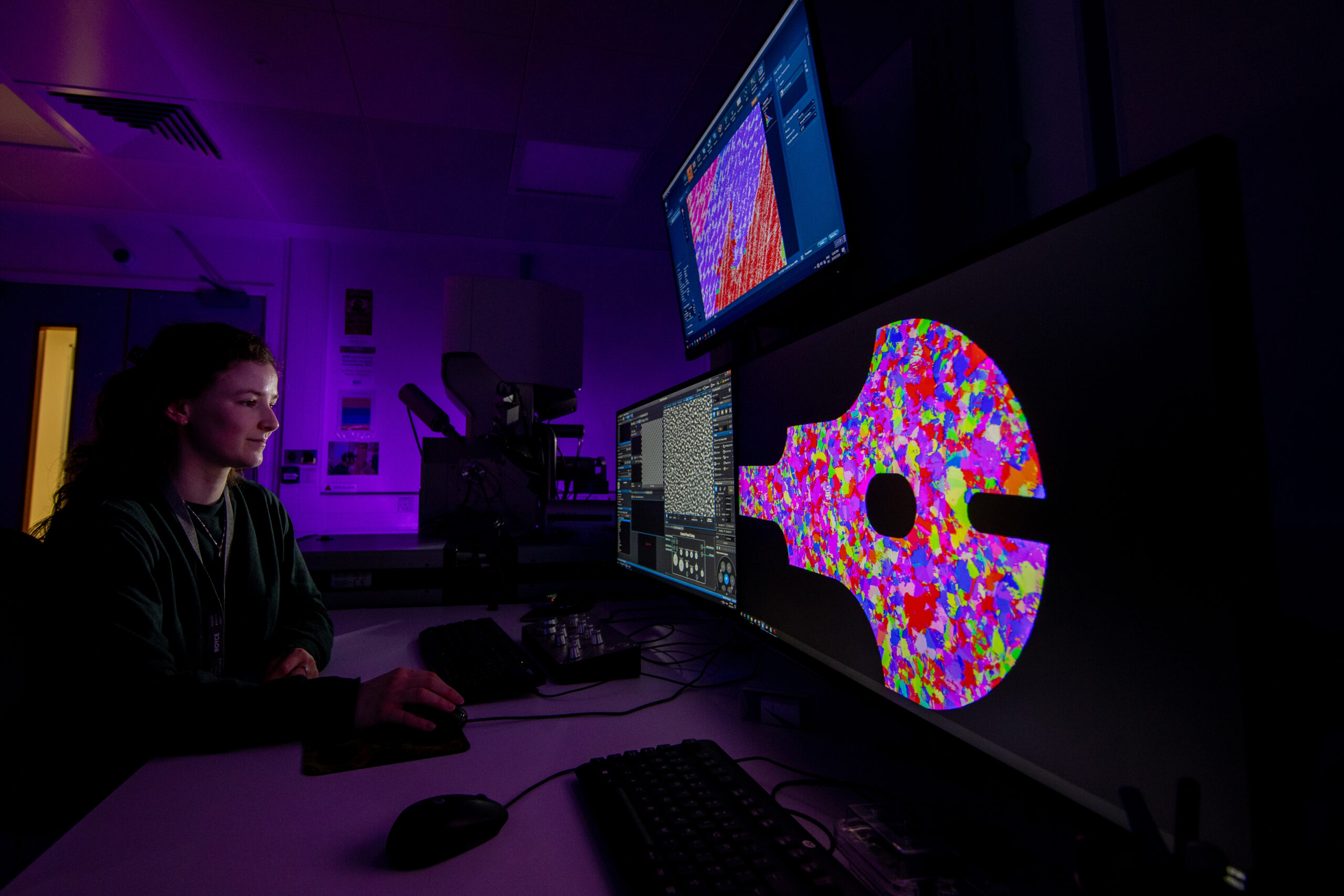

Our CDT offers a comprehensive training programme, using world class facilities in a supportive environment. Key benefits include:

- The Royce Partners collectively possess an unrivalled suite of materials fabrication, characterisation and testing facilities, and world leading expertise.

- Exposure to the Royce national network and industrial collaborators, with one of them co-supervising each project.

- Flexible and inclusive pathways for study, including options for part-time study and the opportunity to study whilst working and being sponsored by your employer. If you have any questions, please contact us to discuss your needs and requirements.

- Fully-funded programme, covering fees, tax-free stipend and a research allowance.

- Cohort-based training will facilitate the development of a network of specialists in Materials 4.0 spread throughout the UK.

- Our comprehensive training programme will help you develop from learners to leaders

Our Centre management team are on hand to answer any questions you may have. Get in touch with them here.

Available Projects

We are currently recruiting new PhD researchers for the following projects:

Please click on the + or – signs to the right of each project title, to expand or hide further details.

High-throughput making, characterising and testing of environmental barrier coatings for data-centric innovation

Prof Ping Xiao

Supervisor

This PhD project will accelerate the development of novel environmental barrier coatings required for ceramic matrix composite components for the next generation of higher temperature aero-engines in collaboration with Rolls-Royce through machine learning. Silicon carbide-based ceramic matrix composites (SiC-SiC CMCs) are being developed to transform aeroengine design by replacing nickel-based superalloys in the hot section of an aero-engine, due to their superior high-temperature mechanical properties and lower density e.g. density of CMCs is about one third density of superalloys. The use of the lighter weight CMCs would allow engine operating at higher temperature, using less cooling air, and therefore fuel. However, environmental barrier coatings (EBCs) are required to protect SiC-SiC CMCs from steam corrosion in engine environment. Without EBCs, the underlying substrates rapidly degrade in the hostile gas-turbine environment, so the failure of the EBCs is life limiting for the entire component. To introduce EBCs into aero-engine service, extensive research on manufacture, characterization and testing of EBCs has been carried out over decades. A range of materials have been investigated, but the current state-of-the art EBCs are based on ytterbium disilicate deposited via the air plasma spraying (APS) process.

Host Institution: University of Manchester

In-situ/operando hydrogen mapping with multi-modal X-ray imaging

Dr Enzo Liotti

University of Oxford

Hydrogen embrittlement (HE) is an unsolved industrial challenge posing a significant constraint on the development of storage, distribution and end-use hydrogen technologies. The specific origin of HE has long been a topic of debate and no precise proposed mechanism exists that is consistent with all the observed HE consequences. In particular, progress in HE mechanisms understanding is hindered by the lack of experimental data regarding hydrogen trapping, the phenomena taking place during cracking and the interaction of hydrogen with microstructural features. Furthermore, to evaluate the behaviour of materials in real-world conditions, the validity of these mechanisms need to be assessed in-situ and dynamically over a broad range of environments – e.g. temperature (from cryogenic to combustion), high pressure, gaseous mixture and varying load. Are existing HE mechanisms still valid at liquid hydrogen temperatures? How is diffusion affected by dynamic conditions, for example when changing temperature and pressure? None of the currently available characterization methods can be used to run in-situ and operando experiments which allow simultaneous mapping of hydrogen within the microstructure whilst assessing the mechanical response under dynamic conditions of load and environment.

Host Institution: University of Oxford

Microfluidic Fabrication and 3D Imaging of Metal and Metal-Oxide Aerogels

Dr Robert Menzel

Supervisor

The studentship will investigate advanced microfluidic techniques to create unique functional aerogel materials, in close collaboration with our industrial partner AWE. The project will follow-on from a previous PhD studentship that successfully developed a microfluidics-based platform for the synthesis of polymer foams with highly controlled internal structures. This studentship will translate the microfluidics synthesis technology to the fabrication of metal aerogels (gold, silver, copper), metal oxide aerogels (tantalum oxide, titanium oxide) and related core-shell materials. The aim of the project is to utilise the high level of control provided by the microfluidic synthesis to produce aerogel materials with unique, bespoke internal microstructures, currently not accessible by other fabrication approaches.

This opportunity is open to UK nationals only.

Host Institution: University of Leeds

Early stage failure prediction in fusion materials using machine learning

Prof Chris Race

CDT Co-Director

In fusion reactors, materials experience extreme temperatures, stresses, and radiation damage. Safe operation requires identification of deformation patterns that are early warning signs of materials failure. These characteristic patterns result from the interaction of deformation mechanisms across multiple scales making detection via traditional analytical methods extremely challenging. This project will apply pattern recognition and machine learning techniques to a large database of experimental data to reveal early-stage fingerprints for damage hidden in the data.

Materials 4.0 Theme: Data-informed metrology for materials science; Materials informatics, data-focused approaches and AI for materials discovery; “Smart” characterisation methods, e.g.

Royce Research Areas: Advanced Metals Processing;

Host Institution: University of Sheffield

Fast and remote ultrasonic tomography using deep learning and laser ultrasound arrays

Dr Theodosia Stratoudaki

Supervisor

This PhD study aims to develop the world’s first laser ultrasound array system for real-time, remote and couplant-free ultrasonic microstructural characterisation of metallic parts using Artificial Intelligence (AI). This system will enable the development, deployment and experimental validation of real-time, in-process, microstructural monitoring of manufacturing processes, a key step towards sustainable and reliable manufacturing of high-value, safety-critical components. In the long term, this material characterisation capability will form the basis of a feedback loop with manufacturing parameters, enhancing control over material properties of parts and enabling bespoke material microstructures.

Host Institution: University of Strathclyde

Supervisors – submit a project

Academic Supervisors

We welcome proposals from supervisors based at our partner universities for postgraduate research projects in Materials 4.0. The research projects must fulfil two basic criteria:

- they must develop a new capability, going beyond simply applying existing methods to create new ways of working within the scope of Materials 4.0; and

- the capability developed must be applicable to multiple sub-domains of materials.

These criteria will ensure PhD researchers develop the knowledge and skills required to drive impactful, ground-breaking research in materials science.

PhD project proposals for cohort 3 (starting Autumn 2026) can now be submitted

Round 1 – NOW OPEN! Deadline: Monday 29 September 2025

Round 2 – Open Tuesday 30 September 2025; deadline: Monday 1 December 2025

Round 3 – Open Tuesday 2 December 2025; deadline: Monday 2 February 2026

Round 4 – Open Tuesday 3 February 2026; deadline: Monday 30 March 2026

If you are interested in submitting a PhD proposal for cohort 3, please get in touch with your local co-investigator – particularly if you are yet to secure industrial funding.

Industry - sponsor a project

Our industry partners can expect:

- Opportunities to shape research in specific areas of interest

- Projects aligned to your organisation’s research priorities

- Collaborations with high-quality students and academic expertise

- Access to state-of-the-art equipment and technical support

- Potential to recruit specially-trained post-doctoral researcher

If you are interested in upskilling your current staff, our PhD at Work option could be exactly what you are looking for.

Contact us for further information.